tungsten carbide coating suitable for many types of components such as engine piston rods, gearbox housings, hydraulic actuators

| Name: | tungsten carbide coating suitable for many types of components such as engine piston rods, gearbox housings, hydraulic actuators |

Product Description

The wear and tear of key components such as automobile engine piston rings and aircraft landing gear hydraulic rods have long plagued the efficient operation and maintenance of the industry. Traditional repair methods have high cost, short life, lack of reliability and other defects, and the high cost of replacing new parts and the risk of production stagnation, further exacerbated the maintenance pressure of enterprises, the following is Jiangyin Deken technology manufacturers will give you a detailed introduction to the thermal spraying tungsten carbide technology with its unique process characteristics and performance advantages, has become an effective technical path for repairing wear parts in the field of automobile and aviation.

Industry pain points: performance degradation and safety hazards caused by wear and tear

In the long-term high-load operation of automobile transmission gears, the dimensional deviation caused by friction will directly affect the transmission efficiency; Aircraft engine blades are continuously washed by high-temperature gas, and material loss can lead to a decrease in structural strength. The traditional electroplating process is prone to coating peeling, long repair cycle and limited corrosion resistance. Welding repair is easy to cause thermal stress deformation, which is difficult to meet the repair needs of precision parts. How to achieve long-term repair and performance improvement has become a technical bottleneck that needs to be broken through urgently.

Tungsten carbide spraying technology: an engineering solution for wear and corrosion resistance

Excellent performance: Tungsten carbide coating has extremely high hardness and wear resistance, and its dense surface structure can effectively reduce the coefficient of friction between metals and delay the wear rate of components. In high-temperature environments, the coating material exhibits excellent stability and can resist fuel corrosion, oxidation and salt spray erosion, especially suitable for harsh working conditions such as engines and drive shafts.

Precise repair ability: Through supersonic flame spraying or plasma spraying process, a uniform covering layer can be formed on the surface of complex curved surfaces and special-shaped structures to restore the geometric accuracy of parts. The technology also eliminates microcracks and surface defects, improving the fatigue strength and stress resistance of the component.

Process compatibility: Whether it is a metal matrix or a composite material, the high bonding strength of the coating to the substrate can be achieved through the adjustment of process parameters, avoiding the problem of spalling caused by the difference in thermal expansion

Technical process: Systematic remediation process steps

Surface pretreatment: Sandblasting or chemical cleaning is used to remove oil and oxide layers, and roughening treatment is used to enhance the adhesion of the coating.

Substrate adaptation treatment: According to the material characteristics of the part, gradient priming or transition layer spraying is selected to optimize the interface bonding performance.

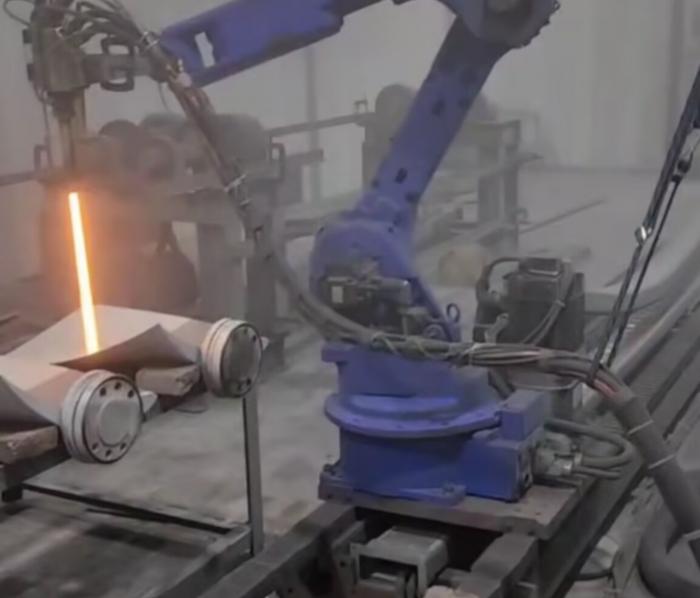

Multi-layer spraying process: high-speed deposition of wear-resistant layers is achieved through supersonic flame spraying, combined with plasma spraying to improve the density of the coating.

Post-processing processing: Dimensional tolerances are restored through precision machining, supplemented by non-destructive testing to ensure that the coating quality meets the standard.

Core advantages: technical adaptability and long-term value

Cost-effective: The repair cost is only 30%-50% of the purchase cost of new parts, and the repair cycle is shortened to 1/3 of the traditional process, which greatly reduces the downtime loss.

Environmental friendliness: reduce the consumption of metal resources and waste generation, in line with the requirements of green manufacturing and sustainable development.

Performance enhancement: After spraying, the surface roughness of the parts is reduced, the coefficient of friction is optimized, and the operation efficiency and energy utilization can be improved simultaneously.

Process flexibility: It is suitable for many types of components such as engine piston rods, gearbox housings, hydraulic actuators, etc., and solves the difficulties of traditional processes